The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Did you know builders say AAC blocks can save up to 30% energy? You get strong blocks that are light. You also make less waste and spend less money. Here are some good things about AAC blocks:

You pay less for the foundation and structure.

You can build faster.

You get better insulation, so you stay comfortable all year.

You help the environment more.

Autoclaved aerated concrete helps you build strong walls. These walls save energy. Many new buildings use this material. It is strong and keeps heat inside. It is also good for the environment. These blocks are lighter than regular concrete. You can carry them more easily.

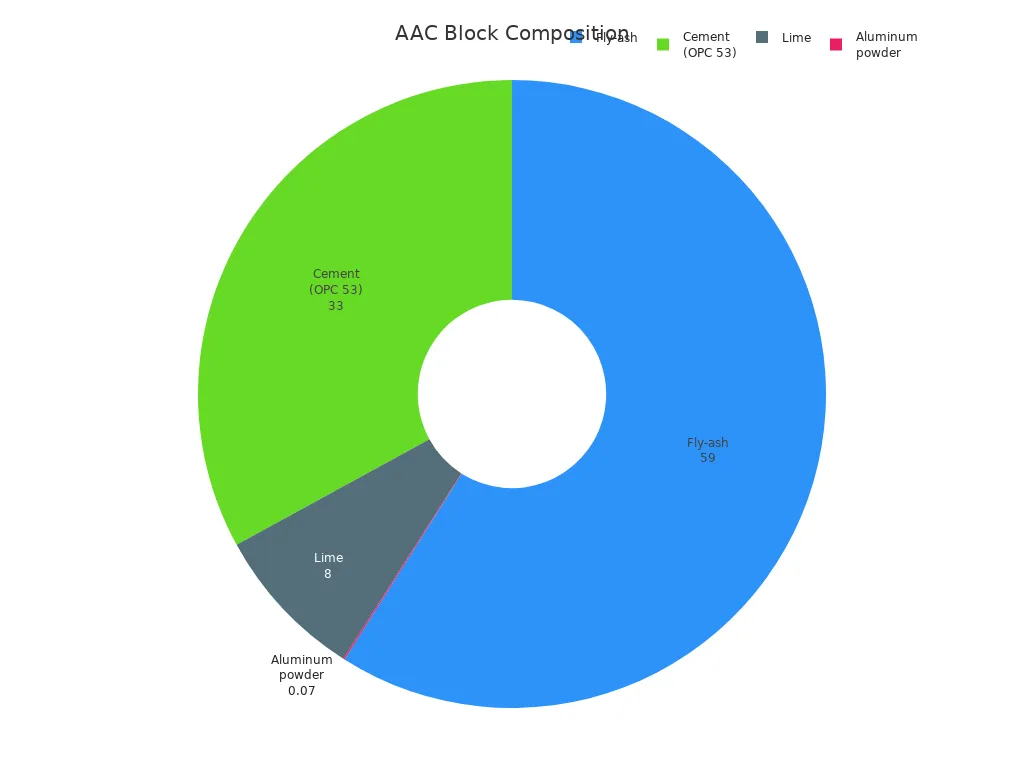

AAC blocks are made from a special mix. The main parts are fly-ash, cement, lime, and aluminum powder. Each part helps make the blocks light and strong. The table below shows what each part does:

Component | Percentage | Contribution to Properties |

|---|---|---|

Fly-ash | 59% | Makes blocks light and helps keep heat in. |

Cement (OPC 53) | 33% | Holds everything together and gives strength. |

Lime | 8% | Helps the block get stronger through a chemical reaction. |

Aluminum powder | 0.07% | Makes air pockets for better insulation. |

You mix these parts together. They react and form the blocks. Steam and pressure cure the blocks. This makes them tough and stable.

AAC blocks have special features. They are different from clay bricks and regular concrete blocks. The table below shows the main features:

Property | Description |

|---|---|

Lightweight | You can move AAC blocks easily. |

Excellent Thermal Insulation | Your building saves more energy. |

Low Pollution Output | Making these blocks causes less pollution. |

High Water Absorption | You must keep the blocks safe from water. |

Poor Adhesion to Mortar | You may need special mortar for these blocks. |

AAC blocks weigh 550-650 kg/m³. Their strength is 3-4 N/mm². Clay bricks are much heavier at 1800 kg/m³. Concrete blocks are also heavier and do not insulate as well. You can read more in guides from Indian Standards and the National Institute of Building Sciences.

Tip: Using autoclaved aerated concrete helps make buildings safer, greener, and more comfortable.

When you pick AAC blocks, you get many good things. These blocks help with more than just saving money. They make buildings strong and safe. They also help save energy and protect the planet.

AAC blocks keep heat in or out very well. Your walls stay cool in summer and warm in winter. This means you do not need to use air conditioning or heat as much. You save energy every day.

AAC blocks have , from 0.1 to 0.7 W/(m·K).

AAC blocks with 400–700 kg/m³ density can reach 0.13 to 0.22 W/(m·K).

Some AAC self-insulation blocks go as low as 0.11 W/(m·K).

You can see how well this works in real buildings:

Metric | AAC Wall | AACS Wall | S Wall |

|---|---|---|---|

Average Daytime Temperature Reduction (%) | 9.11% | 14.31% | N/A |

Heat Load Leveling Reduction (%) | 28.41% | 46.76% | N/A |

Energy Consumption Savings (RMB/m2) | 157.14 RMB/m2 | 195.84 RMB/m2 | N/A |

CO2 Emissions Reduction (g/m2day) | 11.78 g/m2day | 14.69 g/m2day | N/A |

AAC blocks can cut air-conditioning use by 30%. This keeps rooms comfy and saves money. AAC is a top choice for green buildings in homes and offices. The National Institute of Building Sciences says AAC blocks help meet energy rules for new buildings.

Note: AAC blocks help you build strong, energy-saving buildings that last a long time.

AAC blocks are much lighter than regular bricks. Walls made with them weigh 55% less. This makes moving and lifting them easier. It also means buildings are safer in earthquakes.

AAC blocks weigh about one-third of red bricks.

Their big size and light weight make building faster and cheaper.

You can finish jobs quicker and need fewer workers.

AAC blocks can be used in many ways. You can cut or shape them for special designs. This lets you build creative buildings that look different from others. AAC blocks help you try new building ideas.

Tip: AAC blocks let you design and build in many ways. They are great for modern and strong buildings.

AAC blocks block sound very well. They help keep rooms quiet in homes, schools, and offices. The air inside the blocks stops noise from passing through walls.

AAC blocks are also very safe in fires. A 4-inch AAC wall can stop fire for 4 hours. AAC does not burn or make harmful smoke. This makes it a safe choice for all kinds of buildings.

Safety Alert: AAC blocks help keep people safe from fire and noise.

AAC blocks are good for the environment. They help at every step of building:

Factories use solar power to lower pollution.

Water is cleaned and used again to save fresh water.

Machines cut blocks exactly, so there is less waste.

Raw materials come from nearby, so trucks drive less.

Green packaging helps recycle and keeps trash out of landfills.

When you use AAC blocks, you help the earth. You also help make buildings that last and use less energy. Builders like AAC blocks for green building awards and eco-friendly projects.

Did you know? Big projects like Egypt’s new capital saved 30% on costs by using AAC blocks. This is because they are light and save energy.

AAC blocks are strong, keep heat in, and are good for the planet. They are perfect for new buildings that need to save energy and last a long time.

AAC blocks are used in many buildings today. In homes, they are found in tall apartments and special house projects. These blocks are light, keep heat in, and do not burn easily. You can build strong homes that save energy. The table below shows how AAC blocks help in homes:

Aspect | Details |

|---|---|

Properties | |

Usage | Popular for multi-story apartments, reducing foundation loads and time |

Adoption Outlook | Demand for sustainable and energy-efficient buildings is rising |

In offices and stores, AAC blocks help meet safety rules. They keep noise out in busy places. You can finish building faster, so people can use the building sooner. You also spend less on energy and make the building stronger.

AAC blocks can lower building costs by 15% to 20%.

Tall buildings can save up to 43.88% per project.

Lighter beams mean you use less cement and sand.

AAC blocks are put together with thin-bed mortar, only 2-5mm thick. This makes walls smooth and strong. You can cut AAC blocks with normal tools, so building is easy. The table below compares how you build with AAC blocks and regular bricks:

Installation Method | AAC Blocks | Traditional Masonry |

|---|---|---|

Mortar Thickness | Thin-bed mortar (2-5mm) | Thick mortar (10-15mm) |

Material Weight | Lighter, easier to handle | Heavier, requires more labor |

Cutting and Fitting | Easily cut with standard tools | Requires specialized tools |

Speed of Installation | Faster due to reduced material use | Slower due to thicker mortar |

Thermal Insulation | Improved insulation properties | More thermal bridges |

AAC blocks cost between $3.38 and $6.76 each. Regular concrete blocks cost $2.54 to $5.08 each. The total cost for walls is $16.90 to $50.70 per square foot. AAC blocks help save energy and work better, so they are a smart choice for new buildings.

AAC blocks can have problems like cracks, plaster issues, and soaking up water. Some builders do not know how to use them well. The table below lists common problems:

Challenge | Description |

|---|---|

Cracking | Cracks can appear after installation, leading to avoidance |

Plastering issues | Smooth texture can hinder plaster adhesion |

Contractor familiarity | Many contractors lack skilled labor for aac blocks |

Moisture sensitivity | Porous blocks can absorb water, causing damage |

Moisture retention | Pores can retain water, affecting finishes |

To fix these problems, keep AAC blocks dry and use good waterproofing. Pick finishes that work well with AAC blocks. Studies show water can make blocks weaker, so keeping them dry is important. Train workers to use AAC blocks the right way. Building codes like LEED and Energy Star now support AAC for green and energy-saving buildings. You help make buildings strong, green, and useful for many types of projects.

Tip: Pick AAC blocks if you want to save energy, help the planet, and build strong buildings.

AAC blocks help you save money for many years. They make your bills lower and cut down on repairs. Here is how they help with costs:

Factor | Impact on Costs |

|---|---|

Lower energy consumption | You pay less because you use less energy. |

Improved insulation | It costs less to keep buildings warm or cool. |

Minimal upkeep | You do not need to fix things as often. |

The AAC industry is leading the way in being green, using new technology, and building faster.

You help make strong buildings and support a future where every building choice helps the planet.

You get lighter walls, better insulation, and faster construction. Many experts, including the National Institute of Building Sciences, recommend AAC blocks for modern projects.

You can use AAC blocks in bathrooms. Apply waterproof coatings or sealants for best results. This prevents moisture from entering the blocks.

AAC blocks resist fire well. A 4-inch wall can stop fire for up to 4 hours. UL and BIS standards confirm this safety.