The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The World’s Leading Supplier of AAC Production Line

The World’s Leading Supplier of AAC Production Line

Views: 0 Author: Site Editor Publish Time: 2024-08-26 Origin: Site

The construction industry is constantly evolving, seeking innovative solutions to enhance efficiency and sustainability. One such innovation is the use of AAC panels, a lightweight, precast building material with excellent sound and thermal insulation properties.

However, the manufacturing process of these panels is complex and requires state-of-the-art equipment. This is where Jiangsu Teeyer Intelligent Equipment Co., Ltd. comes into play, specializing in the design and manufacturing of AAC panel production equipment.

Backed by over ninety patents, Teeyer's equipment is at the forefront of technology, ensuring a high-quality, efficient AAC panel manufacturing process. In this article, we will delve into the intricate process of AAC panel manufacturing, highlighting the role of Teeyer's innovative solutions.

Understanding AAC Panels

AAC panels stand for Autoclaved Aerated Concrete panels. They are renowned for being lightweight yet robust. These panels offer an efficient alternative to traditional building materials due to their unique properties. The manufacturing process involves creating a cellular structure within the panels, providing excellent insulation. This means AAC panels contribute to energy efficiency in buildings.

Moreover, AAC panels are fire-resistant and can help reduce noise, making them ideal for both residential and commercial projects. Their versatility and durability make them a preferred choice for modern construction.

The Role of Jiangsu Teeyer Intelligent Equipment Co., Ltd.

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a leader in AAC panel production technology. They specialize in designing advanced AAC equipment.

Teeyer prides itself on innovation, holding over ninety patents in the industry. Their patented solutions set them apart in the market.

With a commitment to excellence, Teeyer supports clients with comprehensive project management and maintenance services. This ensures reliable and efficient AAC panel factory operations.

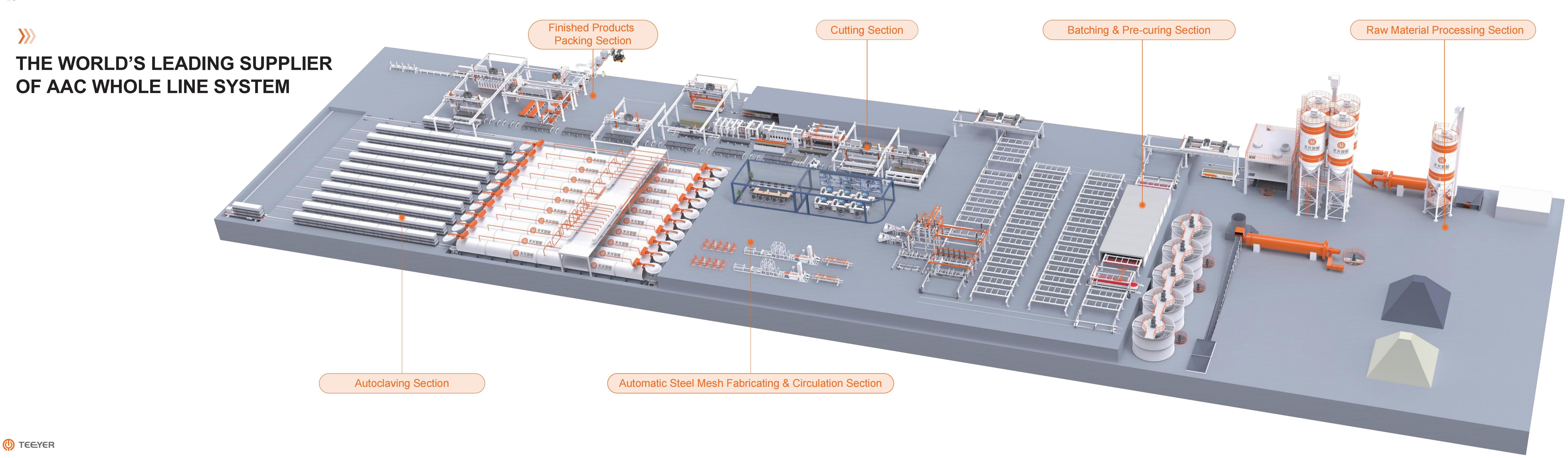

Step-by-Step AAC Panel Manufacturing Process

The AAC panel manufacturing process is a series of well-defined steps. Each stage ensures the production of high-quality panels. Below is an outline of the process.

.Raw Material Preparation

.Dosing and Mixing

.Casting

.Pre-curing

.Cutting

.Autoclaving

.Packaging

1. Raw Material Preparation

The first step is gathering essential raw materials. These include lime, cement, and silica.

Once collected, materials are processed to ensure uniform consistency. This is crucial for quality assurance.

2. Dosing and Mixing

Next, precise dosing of materials takes place. This ensures accurate proportions.

The materials are then mixed thoroughly. Mixing transforms raw components into a homogenous slurry.

3. Casting

During casting, the slurry is poured into molds. These molds define the panel's dimensions.

This stage is critical for forming shape. Proper casting prevents structural flaws.

4. Pre-curing

Pre-curing involves initial curing of the mix. This solidifies the mixture slightly.

Achieving the right temperature and humidity is vital. It prepares the mix for cutting.

5. Cutting

In the cutting phase, partially cured material is sliced. Precision in cutting determines panel sizes.

Teeyer's high-tech equipment ensures exact cuts. This consistency is essential for construction efficiency.

6. Autoclaving

Autoclaving is a key process for strength. Panels undergo high-pressure steam curing.

This step enhances durability and fire resistance. Autoclaving creates lightweight and robust panels.

7. Packaging

Finally, panels are packaged for transport. Quality checks ensure they meet specifications.

Proper packaging prevents damage during transit. This maintains quality from factory to site.

Teeyer's Technological Edge and Patents

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is at the forefront of AAC technology. Their dedication to innovation is unparalleled in the industry.

With over ninety patents, Teeyer ensures advanced design in every piece of machinery. These patents underscore their commitment to excellence and progress.

Their patented technology optimizes every step of the manufacturing process. This innovation ensures top quality and efficiency, providing clients with a significant competitive advantage.

Benefits of Teeyer's AAC Panel Manufacturing for Contractors and Project Managers

Teeyer's AAC panel manufacturing provides unparalleled efficiency for building contractors. The production speed is a true advantage.

Project managers benefit from the reduced labor costs that come with Teeyer's automated machinery. This allows for more efficient budget management.

Additionally, the company's local production reduces project timelines. This ensures faster project completion and delivery.