The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The World’s Leading Supplier of AAC Production Line

The World’s Leading Supplier of AAC Production Line

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

AAC block plants make small, medium, and large autoclaved aerated concrete blocks. These blocks are used in many building projects. The plants use special machines to keep block size and quality the same. Picking the right block size helps the project go faster. It also saves money by up to 20%. Bigger blocks mean fewer joints and less work. The table below lists the most common AAC block sizes and how much they are used:

AAC Product Type | Typical Size Range (mm) | Market Share / Usage Details |

|---|---|---|

Blocks | 600 x 200 x 100–250 | Over 75% of total AAC consumption globally |

Bricks | 240 x 100 x 75 | Over 800 million units used in 2023 |

Autoclaved aerated concrete blocks also make buildings safer and save energy. This is why many people choose them for new buildings.

An AAC block plant is a place that makes autoclaved aerated concrete blocks. The plant uses special machines to help make the blocks. First, workers mix sand, cement, lime, water, and aluminum powder. This mix becomes a thick liquid called slurry. They pour the slurry into molds to make big cakes. The cakes rest for a while to get firm. Then, machines cut the cakes into blocks of the right size. The blocks go into autoclaves, where steam makes them strong. After cooling, workers trim the blocks to make sure they are the right size. The plant checks the blocks for strength, insulation, and water absorption. Finished blocks are packed and sent out for delivery.

Today's AAC block plants use machines for almost every step. Crushers, ball mills, mixers, and conveyor belts help move and mix materials. Cranes and carts move blocks without much lifting by hand. These plants use less energy and make less pollution.

AAC block plants come in three sizes: small, medium, and large. The size depends on how many blocks the plant makes each year. Small plants make less than 100,000 cubic meters of blocks a year. Medium plants make between 100,000 and 300,000 cubic meters. Large plants make more than 300,000 cubic meters each year. Bigger plants have more autoclaves and make more blocks each day. They also use more power. Many big AAC block plants send blocks to other countries and help build large projects.

Plant Size Category | Annual Output Range (m³/year) | Daily Output Range (m³/day) | Power Consumption (KW) | Number of Autoclaves |

|---|---|---|---|---|

Small to Medium Plants | 50,000 to 300,000 | 166 to 1000 | 400 to 900 | 2 to 10 |

Large Plants | 300,000 to 500,000 | 1000 to 1666 | 900 to 1500 | 10 to 20 |

Production capacity means how many AAC blocks a plant can make in one year. The amount depends on the plant’s size, how much it uses machines, and how good the equipment is. Small plants make less than 100,000 cubic meters and sell mostly nearby. Medium plants make up to 300,000 cubic meters for bigger areas. Large plants use more machines and make over 300,000 cubic meters for big building jobs. These plants use smart machines to make more blocks and waste less. High production helps meet the need for AAC blocks in cities and big projects.

Autoclaved aerated concrete blocks are made from a special mix. The main things used are quartz sand, fly ash, lime, Portland cement, gypsum, water, and a little aluminum powder. Workers mix these together to make a thick liquid called slurry. The aluminum powder reacts with lime and water. This makes hydrogen gas. Tiny bubbles form inside the block. The mixture is poured into molds and starts to harden. Then, the blocks go into an autoclave. Heat and pressure make the blocks strong and light.

The quality and amount of each material changes the block’s final features. More silica or fly ash can make the block stronger or lighter. The autoclave helps the block get a solid, airy structure. This makes the block weigh less and insulate better. How the materials are mixed also matters. Good mixing gives even bubbles and stronger blocks.

Autoclaved aerated concrete blocks have many good points over regular concrete blocks. These help builders save time, money, and energy. The table below lists some main benefits and facts:

Benefit Category | Quantitative Evidence / Data | Explanation |

|---|---|---|

Lightweight | AAC blocks have lower density than traditional bricks, reducing dead load and structural requirements. | Leads to savings in steel and concrete, and reduces transportation costs. |

Compressive Strength | AAC blocks exhibit higher compressive strength compared to traditional bricks. | Enhances structural integrity and durability. |

Cost-effectiveness | Construction cost savings of 15-20% reported when using AAC blocks instead of traditional bricks. | Results from reduced material, labor, and transportation costs. |

Market Growth | Projected market growth from USD 17.5 billion in 2023 to USD 39.2 billion by 2032 (CAGR 9.3%). | Indicates increasing adoption driven by AAC benefits. |

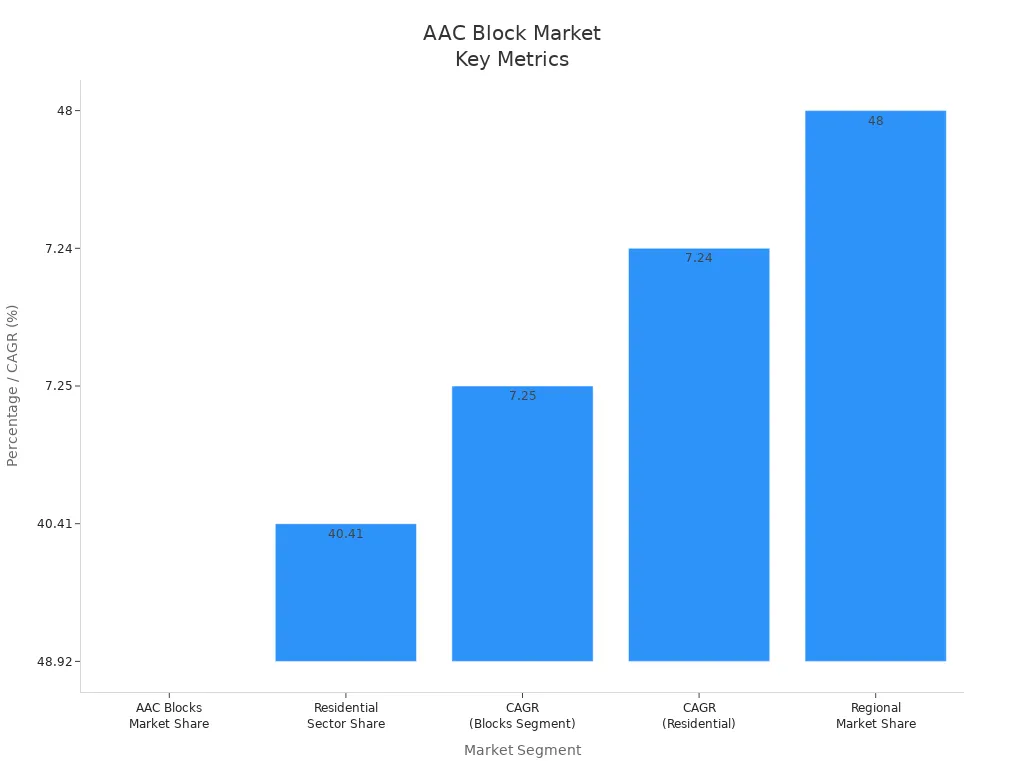

Market Share | AAC blocks held 48.92% share of the global AAC market in 2021; 40.41% share in residential construction. | Reflects widespread acceptance and preference in key construction sectors. |

Thermal & Acoustic Insulation | Superior insulation properties reduce energy consumption for heating/cooling and noise levels. | Supports energy efficiency and comfort in buildings. |

Fire Resistance | AAC blocks provide enhanced fire resistance compared to traditional blocks. | Improves safety in residential and industrial applications. |

Installation Efficiency | Easier handling and faster installation reduce construction time and labor costs. | Accelerates project timelines and lowers overall expenses. |

Autoclaved aerated concrete blocks are lighter than regular concrete blocks. This means buildings do not need as much steel or concrete. The blocks are also stronger, so buildings last longer and are safer. Using AAC blocks can save builders 15-20% on costs. The blocks keep heat and sound out, so buildings stay quiet and use less energy. They also resist fire, which makes homes and factories safer. More people want these blocks, so the market is growing fast.

AAC block plants make autoclaved aerated concrete blocks in many sizes. Each size is used for different building jobs and has its own benefits. Picking a block size can change how fast a project goes, how much it costs, and how strong the building is. The table below shows the usual sizes for small, medium, and large AAC blocks in metric and imperial units.

Size | Length (mm/in) | Height (mm/in) | Thickness (mm/in) |

|---|---|---|---|

Small | 400–600 / 16–24 | 200–250 / 8–10 | 75–100 / 3–4 |

Medium | ~600 / 24 | 200–250 / 8–10 | 150–200 / 6–8 |

Large | 600–625 / 24–25 | 200–300 / 8–12 | 250–400 / 10–16 |

Small AAC blocks are often used for inside walls in homes and offices. These blocks are made to be easy to carry and put in place. Workers use them to split rooms or make walls that do not hold up the building. Small blocks have many good points:

They are light, so workers move them fast and pay less for labor.

They keep heat in or out, so heating and cooling cost less.

They block noise, making places like schools and hospitals quieter.

They do not burn easily and can stop fire for up to 4 hours.

They last a long time and do not get damaged by weather.

They are simple to cut and shape, so building goes faster.

They do not soak up much water, so they last longer.

Bugs like termites cannot eat them, so buildings stay safe.

Small AAC blocks let builders work in tight spaces. Builders can change block sizes to fit special needs.

But, small AAC blocks can be hard to use. Workers need special skills to line up the blocks and use thin mortar. Plants say to use special saws to cut the blocks. Small blocks can cost more than regular bricks and may not be easy to find everywhere. Builders need to plan ahead to get the blocks on time.

Medium AAC blocks are the most common for building. Plants make these blocks for walls that hold up buildings and for outside walls. Medium blocks are about 8" x 8" x 24" or 600 mm x 200 mm x 150–200 mm. Builders use them for both strong and not-strong walls.

Medium blocks are good for walls in short or medium-tall buildings, even in earthquake areas.

They work for inside walls, room dividers, and panels.

Plants make medium blocks to be strong but not too heavy.

Their strength is 35 to 50 kg/cm², so they can hold up buildings with five or six floors.

Medium blocks are better than bricks for weight, heat, and shaking from earthquakes.

Builders save energy, get fire safety, and build faster with these blocks.

Medium blocks are soft, so they need care. Plants say to use special panels and lintels for some jobs. Builders pick medium blocks because they work well for most building needs.

Large AAC blocks are best for building strong walls and foundations. Plants make these blocks up to 625 mm long and 400 mm thick. Large blocks have many pluses:

Fewer joints mean faster work and less cement.

They are easy to cut and move with normal tools.

Bugs and damage do not hurt them much.

They keep heat in or out and do not burn easily.

Making them is good for the planet and saves water.

Even though they cost more to make, the whole project costs less.

Large AAC blocks are half as heavy and ten times bigger than bricks. Builders put up walls fast and save on shipping.

Still, large AAC blocks have some downsides. They cost more to make, so builders must plan their budget. Large blocks can break if not handled right and need skilled workers. Builders must protect the blocks from water and cracks. Plants say to use thicker walls in cold places for better heat keeping. It can be hard to fix things to these blocks because they are full of tiny holes.

The table below shows how small, medium, and large AAC blocks compare for weight, heat keeping, and how fast they go up.

Aspect | Small AAC Blocks | Medium AAC Blocks | Large AAC Blocks |

|---|---|---|---|

Weight (Bulk Density) | 750–850 kg/m³ | 600–950 kg/m³ | 600–650 kg/m³ |

Thermal Insulation | Good, but more joints | Better, fewer joints | Best, minimal joints |

Sound Insulation | High, but joint-dependent | Higher, more uniform | Highest, large uniform size |

Installation Speed | Slower, more handling | Faster, balanced handling | Fastest, fewer blocks |

Construction Method | Wet, double plastering | Wet, single/double plaster | Dry, prefabricated possible |

Typical Applications | Interior partitions | Load-bearing, external walls | Foundations, structural walls |

AAC block plants make different sizes to fit what builders need. The best block depends on the job, how strong the wall must be, and how fast it needs to be built. Builders should talk to AAC block plant experts to pick the right block for their project.

North America uses specific standards for AAC block sizes. Builders follow these standards for both residential and commercial projects. The most common block size in North America measures 8 inches high and 24 inches long. Thickness can range from 2 inches to 15 inches. Jumbo blocks are also available for larger structures. These blocks can reach up to 40 inches in length and 24 inches in height. The table below shows the standard AAC block sizes used in North America:

AAC Block Type | Thickness (inches/mm) | Height (inches/mm) | Length (inches/mm) |

|---|---|---|---|

Standard Block | 2 to 15 (50 to 375) | 8 (200) | 24 (610) |

Jumbo Block | 4 to 15 (100 to 375) | 16 to 24 (400 to 610) | 24 to 40 (610 to 1050) |

Builders often choose standard blocks for residential walls. Jumbo blocks work well for fast construction in large buildings.

These sizes help builders meet local building codes. They also make it easier to plan for insulation and fire safety.

AAC block sizes can change in different countries. Europe, Asia, and Australia each have their own standards. In Europe, builders often use blocks that measure 600 mm in length and 200 mm in height. Thickness can range from 75 mm to 400 mm. In India, the most popular size is 600 mm x 200 mm x 150 mm. Australia uses similar sizes but sometimes prefers thicker blocks for better insulation.

Some countries adjust block sizes for climate or building style. For example, colder regions may use thicker blocks to keep homes warm. Warmer areas may use thinner blocks for better airflow. Builders select block sizes based on the needs of residential or commercial projects.

Note: Always check local building codes before choosing AAC block sizes. This ensures the project meets safety and energy rules.

AAC block plants can make many different block types. They change block size, shape, and density with special molds. This helps builders get blocks that fit their job well. Plants can make blocks longer, taller, or thicker. Some jobs need blocks with slots or grooves. Plants can add these features.

Customization Feature | Description |

|---|---|

Block Size | Length, height, and thickness tailored to project needs |

Block Shape | Special shapes, slots, or grooves for unique designs |

Density | Adjusted for load-bearing or insulation requirements |

Panel Length | Custom panels from 1500mm to 6000mm |

Raw Material Selection | Materials chosen for strength, weight, or local availability |

Custom AAC block sizes help with special building needs. Architects and engineers pick custom blocks for strong walls or better insulation. Custom sizes also help when a job must finish fast or save energy.

Tip: Talk to the aac block plant early about custom blocks. This helps the project get the best blocks:info@teeyer.com

Cutting machines are important in every AAC block plant. These machines use blades and wires to cut blocks to the right size. The plant can set the machine for normal or custom block sizes. Strong motors and frames help the machine work fast and cut well.

Feature Category | Details |

|---|---|

Cutting Mechanism | Adjustable blades and multi-wire systems for vertical and horizontal cuts |

Block Size Range | Supports both standard and custom sizes |

Cutting Thickness | Up to 1500 mm or 200 mm, depending on the machine |

Cutting Speed | Adjustable, usually 2-4 meters per minute |

Safety Features | Emergency stop, safety guards, and overload protection |

Maintenance | Regular blade sharpening and upkeep required |

The plant can fill special orders, but there are limits. The machine can only cut blocks up to a certain thickness. It also needs enough power to work. The machine must be checked and cleaned often to keep it working right. Even with these limits, cutting machines help the aac block plant make custom blocks for many building jobs.

Picking the right AAC block takes a few steps. Builders look at the building type, what the structure needs, the weather, and how much money they have. Each thing changes how AAC blocks work in homes, offices, and factories.

Different buildings need different AAC block features.

Homes use AAC blocks for good heat and sound control. These blocks help keep houses comfy and save energy.

Offices and stores use AAC blocks for walls inside and outside. Builders like these blocks because they last long and save time and money.

Factories need AAC blocks that are strong and stop fire. These blocks work for walls that hold weight or do not.

Factor | Description | Relevance to Building Types |

|---|---|---|

Size and Dimensions | You can get standard or custom sizes for your project. | Bigger blocks make building faster but need care when moving. |

Compressive Strength | Shows how much weight a block can hold. | Offices and factories often need stronger blocks. |

Density | Changes the block’s weight, heat, and sound control. | Heavy blocks are strong but do not keep heat in as well. |

Thermal Insulation | Air pockets in AAC blocks help keep heat in or out. | This is important for homes to save energy and stay comfy. |

What the building needs helps pick the AAC block. Builders mostly use AAC blocks for walls that do not hold up the building. If a wall must hold weight, they pick strong AAC blocks and check the plans. AAC blocks are light, so the building does not need a heavy base or frame.

AAC blocks keep heat in or out very well. They help buildings use 30% to 50% less energy for heating and cooling. These blocks also make rooms cooler or warmer, so they work in hot or cold places. Builders pick the block’s thickness and weight to fit the local weather and save energy.

Money is important when picking blocks. Big AAC blocks cost 30-40% more for each block than small ones. But big blocks need less work and make building faster, so the whole job can cost less. Builders think about the higher price of big blocks and the time and energy they save.

Tip: Builders should pick AAC block size and type that fit the building, weather, and budget for the best results.

Picking the right AAC block size and knowing plant capacity is very important. It affects how strong, cheap, and fast a building goes up. Experts say you should look at things like density, how well it keeps heat in or out, how much sound it blocks, how much water it takes in, the size and shape, if the maker is trusted, and the price:

Density

Thermal conductivity

Sound insulation

Water absorption

Size and shape

Manufacturer reputation

Cost

A lot of builders want to know about normal block sizes, which thickness works for different walls, and how AAC block plants are different from old building materials. To get the best results, talk to an AAC block plant expert and check guides from top plant makers.

Builders often use AAC blocks measuring 600 mm x 200 mm x 150 mm (24 in x 8 in x 6 in) for homes. This size offers a good balance of strength, insulation, and easy handling.

Yes, AAC blocks with higher thickness and density can support load-bearing walls. Engineers check the block’s compressive strength before using them in structural applications.

AAC blocks weigh less and cover more area per block. Fewer joints and faster installation reduce labor and material costs. Builders often report savings of 15–20% compared to traditional bricks. Know more about tips for choosing the best AAC blocks turnkey plant, click here.

AAC block plants can produce custom sizes using adjustable molds and cutting machines. Custom blocks help meet unique design or structural needs in commercial and residential projects.

AAC blocks work best with thin-bed mortar. Builders use special trowels and saws for cutting and placing blocks. This ensures strong joints and smooth wall finishes.