The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The World’s Leading Supplier of AAC Production Line

The World’s Leading Supplier of AAC Production Line

Views: 0 Author: Site Editor Publish Time: 2025-07-22 Origin: Site

An aac block making machine makes light building blocks. It uses sand, cement, lime, gypsum, aluminum powder, and water. These machines are important in building today. They help make many aac blocks quickly. People like aac blocks because they save energy and are good for the environment. Teeyer is a top company in aac technology. They create new ideas and offer smart aac machines that can make many blocks. The aac block market is almost USD 12 billion in 2024.

AAC was ameliorated in the mid-1920s by the Swedish architect Dr Johan Axel Ericksson and Professor Henrick Kreuger at the Royal Institute of Technology. The production of AAC started in 1929 at the city of Yxhult, Sweden. It is growing fast because people want green buildings and better ways to make them.

An aac block making machine is very important in a modern autoclaved aerated concrete block plant. This aac blocks machine mixes things like sand, cement, lime, gypsum, and aluminum powder. It makes blocks that are light. The machine uses special ways to mix, shape, cut, and cure the blocks. Teeyer is a top company in this area. Its AAC Production Line is known for being automatic and saving energy. It can also make a lot of blocks fast. Many other companies look at Teeyer’s machines for ideas. Teeyer’s machines work for both big and small aac plants. This makes Teeyer a trusted choice for people who make aac bricks.

Note: Teeyer's AAC Production Line can make up to 1,000,000 cubic meters of aac blocks every year. This big number helps meet the need for green building materials all over the world.

The table below shows some common details for an aac block making machine:

Specification | Details |

|---|---|

Machine Type | AAC Block Making Machine |

Capacity | 500 blocks per hour or 100 m³ |

Power | 120 kW |

Voltage | 415 V |

Frequency | 50 Hz |

Raw Materials | Fly Ash, Cement, Quick Lime |

Mount Type | Floor Mounted |

Material Used | Mild Steel |

Method | Autoclave Aerated |

Applications | Industrial, Construction |

AAC block making machines have gotten better very quickly. New machines have many helpful features:

They mix all the raw materials very well. The machine can change how long and how fast it mixes to get the same results each time.

The cutting system uses wires or blades. These cut the blocks into the right size and shape. This helps make more blocks and gives a smooth finish.

The curing system uses steam or autoclaving. This controls heat and moisture. It helps the blocks dry faster and makes sure they are all good quality.

High capacity lets plants fill big orders. Some machines can make over 1,000 m³ of blocks in one day.

The cutting is very exact, usually within ±1mm. This means the blocks fit together well.

Mini aac plant can be set up in small or big spaces.

Good support after buying, like help with setup, training, and fixing, keeps the machines working well.

Energy systems and waste heat recovery help save money and protect the environment.

Teeyer's AAC Production Line has all these features. Its machines use a special control system called DCS with Siemens PLC hardware. This system lets different parts work on their own but also be managed together. Teeyer aac block equipment helps stop problems and makes fixing things easier. Teeyer can also change its machines for small or big plants.

There are different kinds of aac block making machines. Each kind is good for different plant sizes and needs. The main types are:

Machine Type | Automation Level | Production Capacity | Suitable Scale | Notes on Operation and Cost |

|---|---|---|---|---|

Manual | Fully manual operation | Low | Small-scale production | Requires full human labor; lower upfront cost; simple upkeep |

Semi-Automatic | Partial automation (mixing and molding) | Medium | Medium-scale production | Some manual work needed; moderate output |

Fully Automatic | Fully automated (mixing, molding, curing) | High | Large-scale production | Minimal labor; high initial cost; top efficiency and quality |

Manual machines need people to do every step. These are best for small or mini aac plants.

Semi-automatic machines mix and mold by themselves but still need some help from people. These are good for medium-sized plants.

Fully automatic machines do mixing, molding, and curing with almost no help. These are best for big plants and work the fastest.

AAC block machine makers like Teeyer have machines for any plant size. Their machines help both new and growing aac plant. New aac plant machinery can also have things like wire cutting, band saws, and even smart AI to make better blocks. Teeyer has supplied AAC plants and services to many countries and regions, and has received excellent reputation and high recognition from our AAC plants users from Indonesia, Kazakhstan,India, the Philippines, Uzbekistan,Myanmar, Malaysia,etc.

AAC blocks are light building blocks used today. They are made from natural and factory-made materials. These blocks have lots of tiny holes inside. This makes them much lighter than regular concrete blocks. Builders use AAC blocks for walls, floors, and roofs. They work in homes and business buildings. AAC blocks keep buildings cool in summer and warm in winter. They are strong and last a long time. Many people pick them for green building projects.

The table below shows how AAC blocks and concrete blocks are different:

Characteristic | AAC Blocks | Concrete Blocks |

|---|---|---|

Composition | Fly ash, cement, lime, gypsum, aluminum powder | Cement, aggregate, water |

Weight | Lightweight, about 50% lighter | Denser and heavier |

Structure | Porous, aerated foam-like structure | Dense and solid |

Thermal Insulation | Excellent insulation properties | Lower insulation properties |

Sound Insulation | Good sound insulation | Less effective sound insulation |

Fire Resistance | Excellent, withstands fire for 2-6 hours | Medium fire resistance |

Handling & Workability | Easy to handle, cut, and shape | Requires special equipment |

Construction Speed | Faster construction, reduces labor costs | Slower installation, higher labor costs |

Application Suitability | High-rise, seismic areas | Low-rise, conventional buildings |

Environmental Impact | Eco-friendly, recyclable | Higher carbon footprint |

Durability | Long-lasting, low maintenance | Prone to cracking, frequent repairs |

AAC blocks are made from a few main things. Cement holds everything together and makes the blocks strong. Lime helps the blocks get even stronger and more stable. Sand or fly ash adds bulk and more strength. Gypsum is added in small amounts to help the blocks set at the right speed. Aluminum powder or paste makes bubbles in the mix. These bubbles make the blocks light and good at keeping heat in or out.

When all these things mix with water, they make a lot of tiny air pockets. These air pockets make the blocks light, strong, and good at keeping buildings warm or cool.

AAC blocks have many good points for builders and owners:

Fire resistance: AAC blocks can stand up to fire for up to 6 hours. This helps keep buildings safer.

Faster and easier construction: Because they are light, workers can build faster and need less help.

Earthquake resistance: AAC blocks are strong and bend a little. This helps buildings stay safe during earthquakes.

Energy efficiency: The air pockets inside AAC blocks keep rooms warm or cool. This helps save money on energy bills.

Year-round availability: Factories can make AAC blocks any time of year. This means building does not have to stop.

Pest resistance: Rodents and termites do not like AAC blocks. The blocks do not get damaged by these pests.

Sound and moisture proofing: The holes in AAC blocks block noise and water. This makes homes quieter and drier.

Design flexibility and cost savings: AAC blocks are all the same size and shape. Builders use less mortar and can make cool designs.

Sustainability: AAC blocks use recycled stuff and make less waste. This is good for the planet.

Note: AAC blocks are light, strong, and keep heat in or out. These things make them a smart pick for green buildings today.

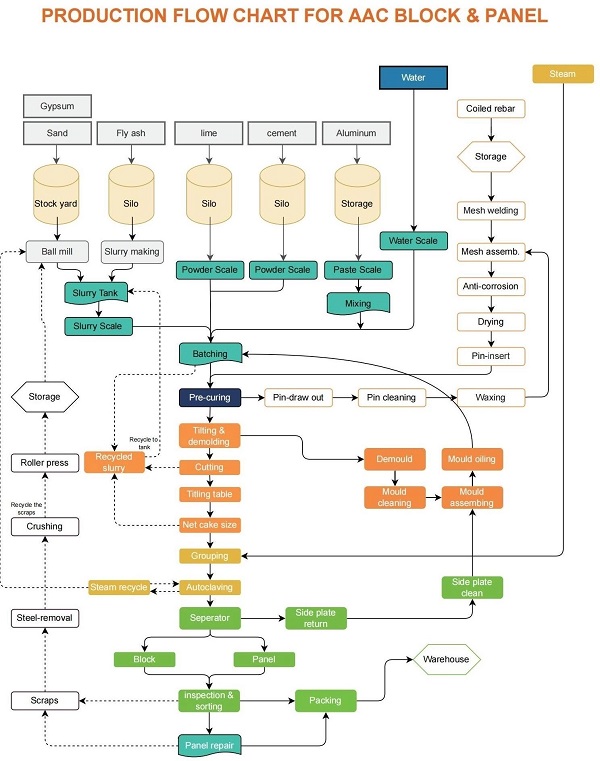

The aac block manufacturing process changes simple things into special building blocks. Every plant follows steps to make sure each block is good. Teeyer uses smart aac block production machines and saves energy. This helps plants make many blocks that are always the same quality.

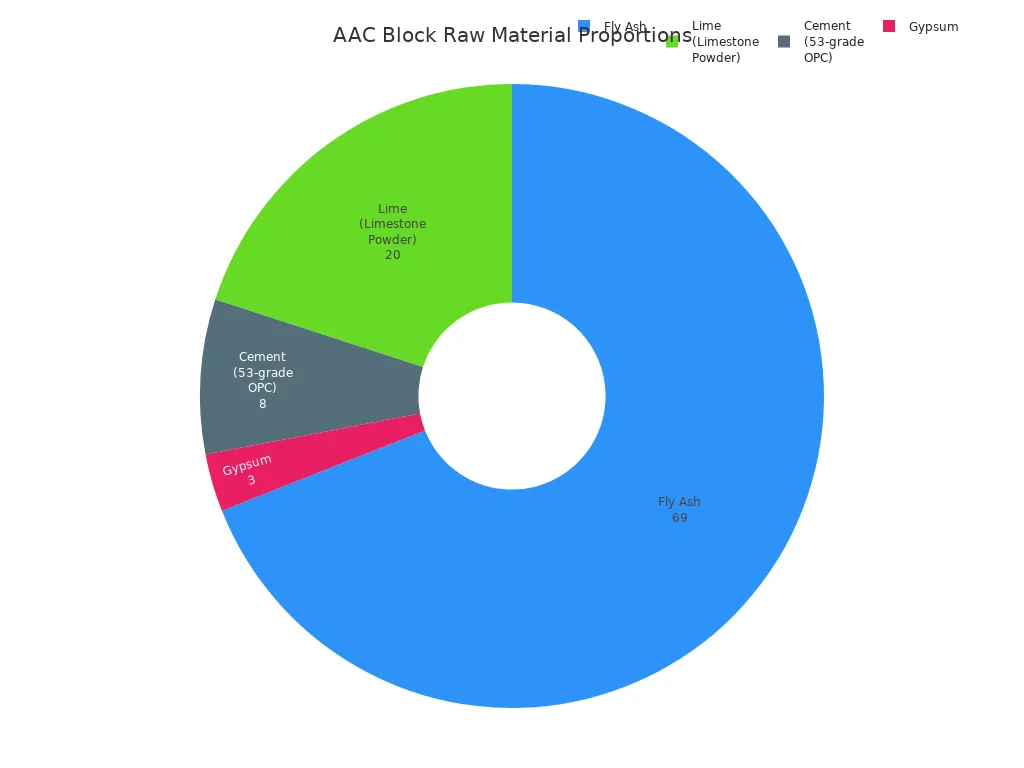

The raw materials used to make aac blocks are very important. Each one helps make the blocks strong, light, and good at keeping heat in or out.

Cement is the main thing that holds the mix together. It gives the blocks their strength. Plants usually use 53-grade Ordinary Portland Cement because it works well.

Lime is often limestone powder. It reacts with silica when heated. This makes the blocks strong and helps them last a long time.

Sand or fly ash gives the mix the silica it needs. Plants pick one based on what is easy to get and the price. Both help make the blocks light and full of tiny holes.

Gypsum controls how fast the mix hardens. It makes sure the blocks do not crack and are easy to work with.

Aluminum powder is very important in the aac block manufacturing process. When mixed in, it makes hydrogen gas. This gas forms small bubbles, so the blocks are light and have air pockets.

Water starts the chemical changes and mixes everything together. The right amount of water is needed for strong blocks.

Plants must measure and mix each raw material very carefully. Even small mistakes can change how good the blocks are.

Here is a table that shows how much of each raw material is used to make aac blocks:

Raw Material | Typical Proportion (by weight) |

|---|---|

Fly Ash | 69% |

Lime (Limestone Powder) | 20% |

Cement (53-grade OPC) | 8% |

Gypsum | 3% |

Aluminum Powder | ~0.08% of total dry ingredients |

Water | Ratio 0.60 to 0.65 (water to dry mix) |

The aac block manufacturing process has many careful steps. Each part uses special machines to make sure everything works well. Teeyer’s machines do many steps by themselves, so there are fewer mistakes and less energy is used.

Preparing the Raw Materials

Workers weigh and get the raw materials ready. They check the quality of cement, lime, sand or fly ash, gypsum, aluminum powder, and water. This step makes sure the mix is right for strong and airy blocks.

Mixing the Materials

The plants put the ingredients in a big mixer. Lime, sand or fly ash, and water make a thick liquid. Workers add cement to make it stable, then aluminum powder for bubbles. This makes the mix even for good blocks.

Pouring and Molding

The plant pours the mix into steel molds. The mix rises a little as bubbles form. The molds shape the blocks to the right size.

Pre-Curing

The blocks sit at room temperature for a few hours. This lets the mix set and makes a “green” cake. The blocks are still soft and ready to be cut.

Cutting

The plant uses special cutting machines to slice the green cake into blocks. Teeyer's cutting machines make sure each block is the right size.

Autoclaving

Workers put the cut blocks into autoclave chambers. The plant uses hot steam at 180-200°C for up to 12 hours. This makes the blocks hard and gives them their final features.

Cooling

The blocks cool down slowly at room temperature. This stops cracks and keeps the blocks strong.

Quality Control Checks

The plant checks each block for size, strength, weight, and insulation. Blocks that are not good enough are used again.

Teeyer's machines watch every step, from mixing to checking the blocks. This makes sure the aac blocks are always good and there is less waste.

Image Source: pexels

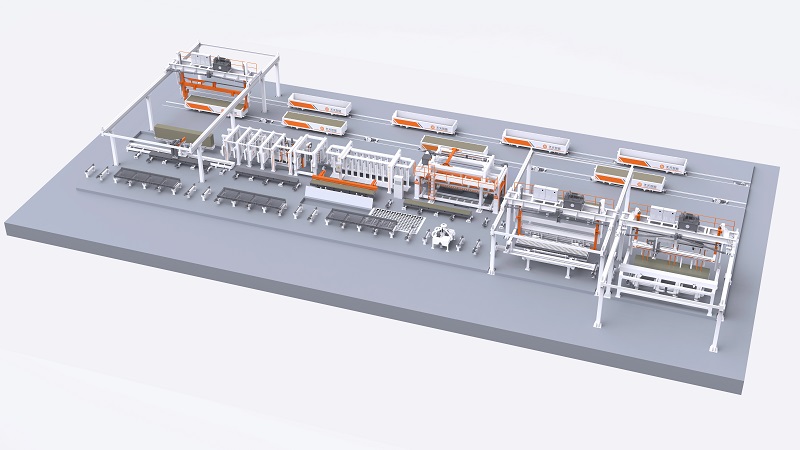

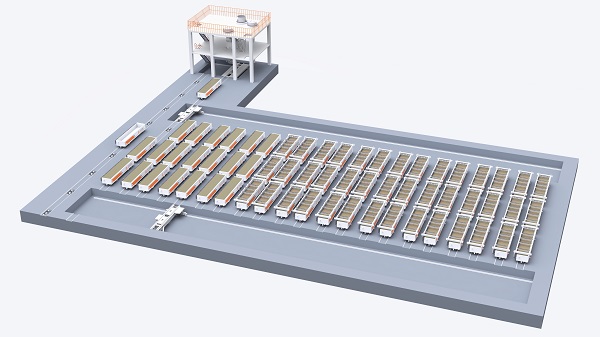

A good plant layout helps an autoclaved aerated concrete block plant work well. The plant starts with storing raw materials. Next, the materials go to mixing, molding, cutting, autoclaving, and packing. Each part of the plant is close to the next one. This makes it easy for workers and machines to move things fast and safely. Teeyer's AAC Production Line shows how to use space in a smart way. The plant has wide paths for forklifts and cranes to move. Sand, cement, and fly ash are stored near the mixing area. The cutting and autoclaving areas are together to save time. Finished blocks go to packing near the exit. This setup saves both time and energy. Plants can be changed to fit local needs, from small to big factories.

Special machines help the plant make good blocks. The main equipment works together so the plant runs well. Here is a table that lists the main machines and what they do:

Equipment Name | Main Function | Key Features / Specifications |

|---|---|---|

Grouping Crane | Lifts and moves grouped AAC blocks or cakes between stations, especially after cutting and before autoclaving or packaging. | Lifting capacity: 5-10 tons; Span: 5-20 meters; Lifting height: 8-15 meters; Fast and accurate positioning. |

AAC Block Slurry Preparation Tank and Mixer | Prepares slurry for AAC block production. | Fully automatic; ensures even mixing; robust industrial design. |

AAC Machine Cement Bin Feeder | Mixes cement for AAC block production. | Fully automatic; industrial-grade reliability and precision. |

Industrial AAC Block Making Machine | Produces AAC blocks with high precision and efficiency. | Fully automatic; durable; suitable for industrial use. |

AAC Block Plate Return Machine | Returns block plates within the production line. | Fully automatic; robust construction. |

AAC Block Rotary Dryer | Dries raw materials like fly ash. | Fully automatic; designed for efficient drying. |

Each machine in the plant has an important job. The grouping crane lifts heavy blocks safely. The mixer and feeder make sure the mix is just right. The main block making machine shapes the blocks. The plate return machine and rotary dryer help keep things moving. Teeyer’s AAC Production Line uses new machines to make more blocks and better quality.

Automation helps the plant work faster and better. Modern plants use control systems to run machines with little help from people. Teeyer’s AAC Production Line uses a DCS with Siemens PLC hardware. This system lets each machine work alone but also connects them for easy control. Automation keeps the blocks good and lowers mistakes. It also saves energy by controlling steam and heat. Many plants use automation to follow green rules. They use natural materials and safe processes. These steps help the autoclaved aerated concrete block plant get awards like CE, ISO9001, and ISO14001. Plants can change product sizes and features to fit local rules and what customers want. Automation, smart energy use, and green ways make today's plant a leader in building.

AAC blocks have many good points for building. These blocks are light, so workers can carry them easily. Walls go up faster because the blocks are not heavy. The blocks are all the same size and shape. This means they fit together well and need less mortar. Building goes quicker and the work area stays cleaner.

AAC blocks keep heat out in summer and keep warmth in during winter. This helps save money on air conditioning and heating. The blocks do not burn, rot, or get ruined by bugs or water. This makes buildings safer and last longer. Workers can cut and shape AAC blocks with simple tools. This lets builders make different designs and waste less material.

Tip: Using AAC blocks helps finish projects on time and saves money. It also makes buildings better.

Modern AAC block making machines help factories a lot. These machines use smart technology and do not need as many workers. This lowers costs and makes work easier. Machines with special motors and heat systems use less power and make less waste. This helps factories save money and work better.

Machines make blocks faster and always the same way.

Special designs use less electricity.

Good mixing and cutting means less waste.

Machines can make blocks in many sizes.

Small setups save space in the factory.

Remote checks and smart fixes keep machines working.

Automatic checks make sure every block is good.

Making AAC blocks is better for the earth than making regular concrete blocks. Factories use fly ash, which is left over from other work. This means less trash goes to landfills and less cement is needed. The blocks are light, so trucks use less fuel to move them.

AAC blocks keep buildings warm or cool, so people use less energy. Studies show that AAC blocks with fly ash can cut CO2 by over 80% compared to concrete blocks. This big change happens because factories use recycled things and less cement. Making AAC blocks also uses less water and makes less pollution.

Using fly ash means less trash in landfills.

Less cement means less carbon in the air.

Light blocks save energy when moved.

Good insulation means less energy in buildings.

AAC blocks are better for the planet than concrete blocks.

Note: Picking AAC blocks helps the earth and keeps it safe for the future.

All autoclaved aerated concrete block plants have problems during production. Many factories find cracks, holes, or hidden problems in blocks. These issues make the blocks weaker and not as strong. Bad blocks mean more waste and higher costs for the plant. People checking by hand often miss small problems, so quality drops.

To fix this, many plants use new technology. AI systems can find cracks and problems right away. These systems use cameras and smart computers to check each block. With AI, plants waste less and make better blocks. Watching blocks in real time helps fix problems fast and keeps work going.

Quality checks are very important too. Plants test raw materials for what they are made of and how fine they are. They watch the mixing, check heat, and control pressure when steaming blocks. Finished blocks are tested for strength, size, and how well they insulate. These steps help make sure the blocks are strong and safe.

Regular care keeps an aac plant working well. Machines work hard every day and need to be looked after. If not, they can break or make bad blocks. Workers must clean mixers, check wires, and look at autoclaves often. Oiling moving parts and changing old pieces stops sudden breakdowns.

A good plan has daily checks and set times for repairs. Many plants use computers to watch machine health. These systems warn workers before things get worse. Training workers to spot early problems also helps. When a plant follows a strict care plan, it avoids costly stops and keeps making blocks.

Starting and running an autoclaved aerated concrete block plant costs money. The biggest cost is buying the main machines. For example, a small plant making 17 m³ a day may cost about Rs. 19 lakh plus tax. Other costs are for materials, worker pay, and power bills. Many plants use loans to start, which means paying interest each month.

Profit depends on how well the plant works. If the plant runs at 60% efficiency, it can still make money after costs. How much people want aac blocks, material prices, and selling price all change profits. Other things that matter are where the plant is, how skilled the workers are, and how much is automatic.

When picking an aac plant, owners should look at market needs, local rules, and their budget. Choosing the right size and automation helps save money and make more profit.

AAC blocks are now a top pick for building homes. Builders use them for walls, room dividers, and sometimes even for the base of houses. These blocks have many good points. They help make homes safer, more comfy, and save energy. Because AAC blocks are light, they do not put much weight on the ground. This is very helpful for tall buildings with many floors. People who live in these homes notice it is quieter and cooler inside. This is because AAC blocks block noise and keep heat out or in. The blocks also do not burn easily. Bugs and water do not harm them, so homes last longer and stay safe.

The table below shows how AAC blocks work in homes:

Performance Factor | AAC Blocks Benefits in Residential Context |

|---|---|

Thermal Insulation | Air pockets inside keep homes cool in summer. This means less energy is needed for cooling. |

Structural Strength | They are strong enough for walls that do not hold up the roof. This lets builders design homes in many ways. |

Weight | They are very light. This lowers the cost for the base and frame of the house. |

Construction Speed & Labor | They are easy to move and fit together well. This makes building faster and costs less for workers. |

Builders can cut, drill, or shape AAC blocks without trouble. This makes building quicker and there is less waste. Making AAC blocks is also better for the earth. This helps builders who want to make green homes.

AAC blocks are used in many big buildings now. Builders pick them for hotels, offices, hospitals, and schools. These blocks follow world safety rules, so buildings are safe and strong. AAC blocks do not catch fire easily. This is important for places that need to be very safe. Bugs and water do not hurt these blocks, so buildings last longer.

AAC blocks keep rooms at a good temperature. This saves money on heating and cooling.

Because they are light, it is easy to move and put them in place. This makes building go faster and costs less for workers.

The blocks are all the same size and shape. This makes walls smooth and saves money on finishing.

They are strong and can handle earthquakes. This keeps people safe in big buildings.

Builders like that AAC blocks are made in a way that is good for the planet.

Using AAC blocks means less pollution and helps build in a green way.

All these things make AAC blocks a smart choice for big and tall buildings.

AAC blocks are important for building in a way that helps the earth. Because they are light and big, trucks use less fuel to move them. This means less pollution. The blocks keep heat in or out, so buildings use about 25% less energy for heating or cooling. AAC blocks do not burn or get ruined by water. This helps buildings last longer and need less fixing.

Feature | Contribution to Green Building and Sustainability |

|---|---|

Lightweight & Large Size | Less energy is needed to move and build with them. This lowers pollution. |

Thermal Insulation | Buildings use less energy for heating and cooling. |

Recyclability | Leftover pieces can be used again. This means less trash. |

Fire Resistance | Makes buildings safer and last longer. |

Moisture Resistance | Stops water damage and keeps buildings strong. |

Use of Natural Raw Materials | Helps make buildings that are better for the earth. |

Faster Workability | Building goes faster and uses fewer resources. |

Builders can crush old AAC blocks and use them again. This cuts down on trash and saves materials. Using AAC blocks helps builders meet green rules and build for a better future.

AAC block making machines help builders work faster and save energy. These machines also make blocks that are always good quality. Teeyer's AAC Production Line is special because it uses smart controls and works by itself. It also gives strong help to users. When picking a plant, companies should think about how many blocks they need. They should also look at how much of the work is automatic and how much energy the plant uses.

Experts say to pick a plant size that fits what people want to buy. They also say to check block quality often and choose a company that helps when needed.

Factor | Practical Advice |

|---|---|

Production Capacity | Make sure the plant makes enough blocks for your needs |

Automation Level | More automation means the plant works better |

Maintenance & Support | Choose a plant that helps fix problems quickly |

An AAC block making machine mixes different materials together. It pours the mix into molds to shape the blocks. Then, it cuts the blocks to the right size. The machine uses steam to cure the blocks. These blocks are light and strong. Builders use them in many new buildings.

Most AAC plants finish making blocks in 12 to 18 hours. This time includes mixing, molding, cutting, steaming, and cooling. Each step helps make sure the blocks are good quality.

AAC block machines use sand or fly ash, cement, lime, gypsum, aluminum powder, and water. Each one helps make the blocks light, strong, and good at saving energy.

Builders like AAC blocks because they are light and easy to move. They keep buildings warm or cool and block noise. These blocks do not burn, get bugs, or soak up water. This makes buildings safer and more comfy.

Yes, companies like Teeyer can change AAC plants for any size. Plants can be small, medium, or large. This helps builders get what they need for each job or market.

Automation means machines do more work instead of people. This makes blocks faster and always the same. Special systems watch every step to save energy and cut waste.

AAC blocks use things like fly ash that would be thrown away. They need less energy to make and move. The blocks keep heat in or out, so buildings use less power. This helps the planet and supports green building.

Machines need to be cleaned and oiled often. Workers should check them to find problems early. Regular care stops breakdowns and helps machines last longer. Many new plants use systems to spot trouble before it gets worse.