The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The World’s Leading Supplier of AAC Production Line

The World’s Leading Supplier of AAC Production Line

Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

AAC block machinery manufacturers are at the forefront of innovation in autoclaved aerated concrete technology. These manufacturers play a crucial role in providing green building solutions for modern construction projects. By 2025, the Asia-Pacific region, including Japan, is expected to be the largest producer and consumer of AAC block machinery. Leading companies such as Xella, MASA, and H+H International excel in producing advanced block machines. The Asia-Pacific region contributes over 35% of the total revenue growth in the AAC market, highlighting its significant impact on construction trends. AAC block machinery manufacturers worldwide focus on precision engineering and sustainability. Choosing the right AAC block machinery manufacturer is essential for selecting the best block making machine supplier for any building project.

Image Source: pexels

Being a leader in AAC block machinery is not just about selling a lot. Top AAC block machinery makers set new standards for new ideas and automation. They work hard on research to build better machines for builders. These companies use smart systems and robots to make more blocks faster. This helps them save money on workers. They check every step to make sure each block is the same and good quality.

Reports say top AAC block machinery makers care about saving energy and being green. They make new ways to cure and autoclave blocks that use less power and work faster. Many companies offer hybrid AAC products and modular systems. These help builders finish projects quicker and with less waste. Their promise to follow green building rules like LEED and BREEAM makes them trusted and well-known.

AAC block makers get top spots by meeting tough rules. The best ones use the newest technology and lots of automation for great products. They can change how much they make to fit each project. Their machines work well and do not break often. Good blocks are light, keep heat in, stop fire, and block noise.

Important things to look for in AAC block machinery makers:

Use of new manufacturing technology

Big production ability and can grow

Automation that saves money and keeps quality

Strong care for the environment

Good prices and saves energy

Machines that work well and are easy to fix

Blocks that are the right size and high quality

Can help with many kinds of building jobs

AAC block makers with good names and lots of experience always make blocks that meet the rules. Their focus on new ideas, being green, and making good products helps them stay successful around the world.

Image Source: pexels

Autoclaved aerated concrete has changed how people build things. AAC is light, so workers can move it easily. This helps save money on labor and makes building faster. Builders like AAC because it keeps buildings warm or cool. This means people pay less for heating and cooling.

AAC blocks do not burn easily. They can stand heat up to 1,200°C. These blocks also block noise, so rooms are quieter. Even though AAC is light, it is still strong. It lasts a long time and works for many building types. AAC is made from natural stuff and uses things like fly ash. This helps the planet and cuts down on pollution.

AAC blocks are big and fit together well. This means builders use less material and waste less. Workers can cut and shape AAC blocks without trouble. This lets them build in many ways and finish faster. Making AAC blocks uses less energy than making regular bricks. This makes AAC even better for saving energy.

Main AAC technology benefits:

Light but strong, lowers building costs

Keeps heat in and blocks sound

Does not burn and keeps bugs out

Quick and easy to build with less waste

Good for the earth and can be reused

Works for homes, offices, and factories

Studies show AAC blocks can cut energy use by half. AAC lasts a long time and is a smart pick for new buildings.

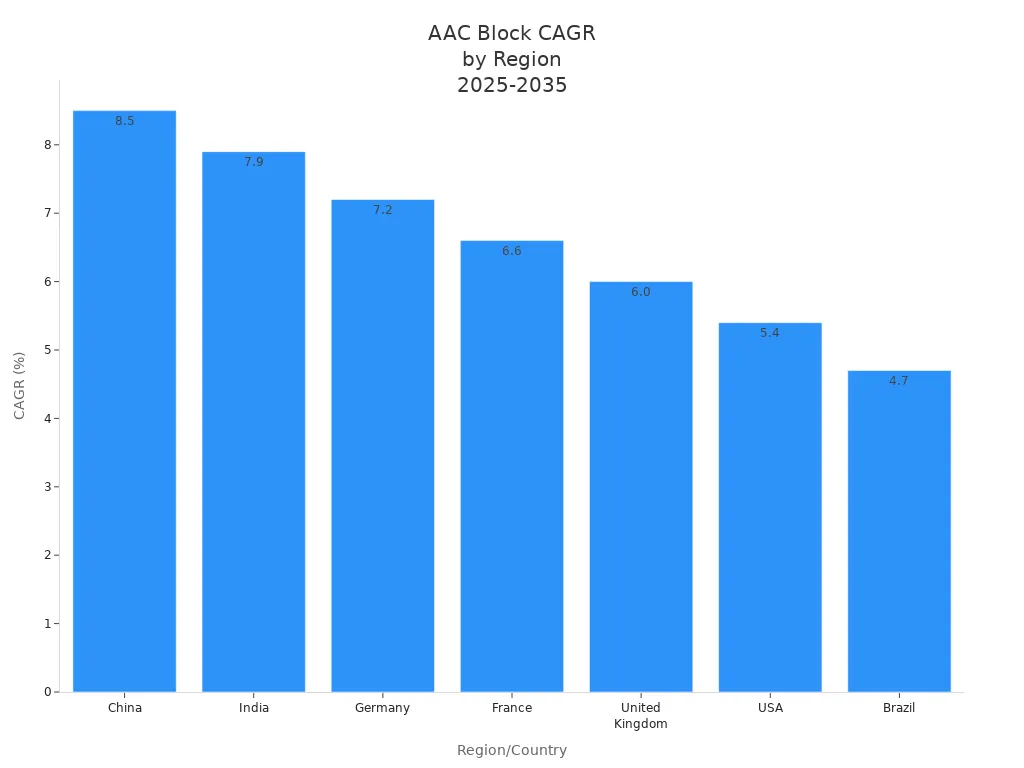

More builders use AAC now than five years ago. People want AAC because cities are growing fast. Governments want green buildings and better energy use. China and India use AAC most for big housing and roads. Europe and North America care about saving energy and getting green awards. Latin America and the Middle East are starting to use AAC more for new buildings.

Region/Country | CAGR (2025-2035) | Key Adoption Drivers and Trends |

|---|---|---|

China | 8.5% | Cities growing, green rules, more machines in AAC |

India | 7.9% | New roads, cheap homes, eco-friendly plans |

Germany | 7.2% | Saves energy, does not burn, follows EU rules |

France | 6.6% | Keeps heat in, stops water, fixes old buildings |

United Kingdom | 6.0% | Green awards, quick homes, ready-made AAC panels |

USA | 5.4% | Likes new ideas and saving energy |

Brazil | 4.7% | Stable money, new tech in building |

AAC is growing because builders like ready-made parts and blocks that fit. Top companies use smart machines and study new ways to make AAC. The AAC market will grow by 7.5% each year worldwide. Homes and offices need more AAC because it saves energy, is light, and helps the earth. AAC is a top choice for new building problems.

Germany is the main place for AAC block makers in Europe. Companies like Xella Group, H+H International A/S, Hebel, and KNAUF Gips KG are top in the market. They use smart engineering and sell blocks to many countries. Reports show Germany works hard on automation and green ways to make blocks. The UK, France, and Italy also help by using computers and caring for the earth. Europe has rules and money for research that help new ideas grow. This makes European AAC blocks very good and strong in the market. These companies make blocks that pass tough tests and help build big projects all over Europe.

European AAC block makers get help from their governments and work with other countries. This helps them make better machines and grow their business.

Leading European AAC block manufacturers in 2025:

Xella Group

H+H International A/S

Aercon AAC

Hebel

ACICO

Ultralite

Forterra

KNAUF Gips KG

Eastern Concrete Materials

Cemex

Global AAC

Strobel AG

China's AAC block makers work in big groups in Shandong, Guangdong, Jiangxi, and Guangxi. These groups help them share ideas and make more blocks for less money. Companies like Jiangsu Teeyer and Hongfa Group are leaders. They make cheap AAC blocks and use smart machines. Their factories are huge, bigger than 10,000 square meters. This means they can make lots of blocks and keep them good. Chinese makers follow world rules like ASTM and ISO 9001. Their blocks work for many building jobs around the world. They help other companies by giving advice and special solutions.

Key features of Chinese AAC block manufacturers:

Good supply chains and easy ways to ship blocks

Outside checks and tracking of materials

Green ways to make blocks that cut waste and pollution

PLC control systems for fast and exact work

Studies say China is great at making cheap AAC blocks that still meet all the rules.

Turkey’s AAC block makers are known for saving energy and building fast. Companies like AKG Gazbeton and AAC Plant Solutions spend money to make better machines. Turkish makers sell blocks for homes, offices, and roads. Their blocks meet rules in Europe and the Middle East. These blocks help builders finish quickly and protect nature. Experts say Turkey is selling more blocks to other countries and mixes ideas from Europe and Asia.

Indian AAC block makers help build more homes and buildings in India. Buildmate and Worldmap Autocontrol System are top companies. They give good machines and help builders with advice. Indian makers make AAC blocks that help save energy and follow green rules. They keep prices low and let builders pick what they need. Reports say India cares about green building and uses more AAC blocks each year.

HESS Group is a top AAC block machine maker. They build AAC KBT plants that work by themselves. These plants are very modern in the Middle East. The plants make blocks and panels with special machines. Their main machines are Multimat RH 2000-3 and RH 760. These machines make blocks fast and are safe to use. The RH 2000-3 uses old and new ideas to work well. It saves money and works without problems. The RH 760 makes blocks in less than six seconds. It can use old moulds, so it is easy to change. HESS Group always tries new things and builds strong machines. Their AAC systems help save energy and make homes better. HESS Group helps concrete makers all over the world do well for a long time.

AAC KBT plants make blocks and panels by themselves

Special machines for making lots of panels

Main machines: Multimat RH 2000-3 and RH 760

Always trying new ideas and strong designs

AAC systems save energy and help people live better

Reports say HESS Group cares about making good machines and new ideas. This makes them a trusted company for AAC block machines everywhere.

Masa Group is one of the best AAC block machine makers in Europe. They build full AAC plants for mixing, cutting, and heating. Their machines make blocks and panels that are always good quality. The machines use smart systems to save money and work faster. Masa Group helps customers with training and support. They want their customers to make the best blocks. Their new ideas and care for customers make them well-known in AAC.

Ytong Technology is part of Xella Group. They lead in making AAC block machines with smart systems. Their blocks are light and keep heat in. The machines use robots to make blocks the same every time. Ytong helps builders with advice and keeps finding new ways to make AAC better.

SKM GmbH makes AAC block machines that last a long time. Their machines help builders make good blocks for many jobs. SKM builds strong machines that are easy to use. They care about making good products and helping customers. Many builders in Europe like SKM for AAC blocks.

WKB Systems GmbH builds AAC block machines that help the earth. They use IMSD and DfE to cut waste and save money. Their Green Separating Machine and IHGT help builders use less material. The machines use little energy and work by themselves. WKB helps builders recycle and meet green goals. Their machines are strong and use less power.

IMSD and DfE help cut waste

Green Separating Machine and IHGT save materials

Machines use less energy and work by themselves

Help with recycling and green building

Reports say WKB Systems GmbH is a leader in green AAC block making. They follow new rules for building that help the planet.

H+H International A/S is a big name in AAC block machines. They work in North America, Europe, Asia Pacific, Latin America, and Africa. H+H gives builders smart AAC machines and good blocks. China and India use their machines a lot because cities are growing. H+H helps builders use green materials for many kinds of buildings. Reports say AAC will keep growing, and H+H is a top company for new ideas.

Work in many places around the world

Smart AAC machines and good blocks

Help builders use green materials

Make blocks for homes and big buildings

AKG Gazbeton is a top AAC block machine maker in Turkey. They sell blocks in Turkey and other countries. AKG Gazbeton cares about making good blocks and helping customers. Builders trust AKG Gazbeton for strong AAC blocks. They help many builders in different places.

Reports say AKG Gazbeton is a trusted company for AAC blocks. They help builders in Turkey and other countries.

AAC Plant Solutions makes AAC block machines that fit what customers need. They build machines for sand, fly ash, and mine slag. Their plants can make different amounts of blocks each year. AAC Plant Solutions sells machines in more than 30 countries. They have special cutters for panels and lintels. The company helps with fixing, checking products, and quick answers.

Machines for many kinds of materials

Plants can make lots or few blocks

Special cutters for panels and lintels

Help with fixing and quick answers

Lontto makes AAC block machines with smart controls. Their machines use PLC, remote checks, and smart tests. They have strong parts and save energy. Lontto’s machines change molds fast and move materials by themselves. They use less water and work with recycled stuff. Some plants use solar power. Lontto’s plants check quality all the time and help builders make good blocks.

Smart controls and robots

Strong parts and save energy

Use less water and recycled materials

Plants work by themselves and check quality

Teeyer has made AAC block machines for over 35 years. They made the first air-tilting cutter and full robot lines. Teeyer has a smart team and works with schools to make better machines. Their lines use green cake separators and smart steel mesh makers. Teeyer helps builders with custom machines and support. They sell machines in Indonesia, Uzbekistan, and Thailand. Teeyer changes machines to fit local needs.

Reports say Teeyer is great at new ideas and working with other companies. This makes them a strong AAC block machine maker.

Buildmate is a top AAC block machine maker in India. They use smart ideas and strong engineering. Buildmate helps builders make good AAC blocks and build green. Their machines are trusted in India for making blocks. Buildmate knows a lot about building machines and is reliable.

Worldmap Autocontrol System Pvt. Ltd. sells many kinds of AAC block machines. They make small, medium, and big AAC plants. Worldmap uses robots and smart systems to help builders work faster. Their machines move blocks, pack them, and handle materials. Worldmap’s machines are used in India and other countries.

Small, medium, and big AAC plants

Robots and smart systems for moving blocks

Machines for packing and moving materials

Dry mix plants and fly ash brick machines

Zenith is a top AAC block machine maker in Germany. Their machines use smart systems and make many kinds of blocks.

Competitive Aspect | Description |

|---|---|

Vibration System | Table with many vibrators and motors for strong blocks. |

Hydraulic System | Two high-pressure systems with touch screens for easy use. |

Aggregate Feeding System | Feeder moves concrete evenly and cleans itself. |

Automation and Versatility | Machines work by themselves and make many kinds of blocks. |

Zenith 940 Model Features | Mobile, makes layers, saves money, lasts long, and works fast. |

Product Range | Makes hollow blocks, interlock, curbstone, bricks, trays, wells, and parts. |

Technology Integration | Uses mechanical, electrical, and hydraulic systems for strong blocks. |

Zenith's machines help builders make good AAC blocks and other concrete parts. They work fast and help with many building jobs.

AAC block makers use smart machines and new technology. Many factories have Industry 4.0 systems. These include AI that checks quality and IoT that helps fix problems before they happen. These upgrades help factories make more AAC blocks with fewer mistakes. More than 65% of AAC plants use machines that work by themselves or with some help. These machines make more blocks and keep mistakes low, about 0.8%. Teams use real-time dashboards to find problems fast. This cuts down on waiting time by 25%. Companies like Jiangsu Runding and Teeyer use full automatic lines and special automation. These changes help every AAC block stay strong and the same.

Main automation features:

Machines mix and batch by themselves

Cutting is exact and autoclaving is better

Molds can be changed fast for new jobs

Cloud systems give quick updates

Top AAC block machine makers offer many products and ways to change them. Teeyer gives full AAC machines, like autoclaves, mixers, and cutters that can be adjusted. Customers pick how dense, strong, or big they want their blocks. QGM and Lontto sell both small and big AAC block plants. Hydraform makes green machines for country areas. Makers design machines for blocks, panels, bricks, lintels, and more. Custom choices depend on plant size, materials, and what the project needs. This helps builders get the right blocks for every job.

AAC product types:

Blocks, panels, bricks, roof and floor boards, lintels

Soundproof panels, pavers, precast parts

AAC block machine makers are different in how they help around the world. REIT works in over 100 countries and sends engineers to help set up, train, and fix machines. Dongyue Machinery Group has offices in five countries and helps with over 1,200 projects. Teeyer has teams ready to solve problems and train workers fast. Good support keeps plants running well and blocks high quality.

Manufacturer | Global Coverage | After-Sales Service Features |

|---|---|---|

REIT | 100+ countries | Engineers travel, set up, train |

Dongyue Machinery | 50+ countries, 5 offices | Local help, lots of project experience |

Teeyer | Customer-focused | Fast team, quick help, training |

AAC block makers care about saving energy and helping the earth. Many have ISO 9001, CE Marking, and Pressure Vessel Certification. ECO-CARE Building Products and Ultratech Cement make AAC blocks with less energy and green materials. Siporex India works on new ideas to help nature. Heat recovery, strong motors, and solar drying cut energy use by up to 40%. These steps help the world build greener and make AAC blocks last longer.

Experts say AAC block makers who save energy and care for the earth earn trust and respect in the world market.

Picking the right block making machine supplier is very important. It can help your building project do well. In 2025, people want suppliers with new technology and good green habits. Reports say aac block making machine suppliers with good names are best at new ideas and working fast. Buyers should look at how long the supplier has worked, what block making machine models they have, and if they can change machines for different jobs. Suppliers who work in many countries can give better parts and service.

Checklist for evaluating a block making machine supplier:

How many years making aac block making machines

Many block making machine choices for big or small jobs

Good record in building projects

Cares about saving energy and being green

Happy customers and good reviews

After-sales support is very important when picking a block making machine supplier. Top suppliers teach customer teams, fix machines, and help fast when there are problems. Good support and feedback help customers fix things quickly. Reports say suppliers who help after sales make sure customers lose less time and blocks are better. Training helps workers use the block making machine safely and well.

Tip: Always ask about support and training before you choose a supplier.

Price is important, but getting good value and return on investment (ROI) is even better. The best block making machine supplier gives machines that last long, use less energy, and make strong aac blocks. Customers should look at price, how long the machine will last, how much it costs to fix, and how much energy it uses. A supplier who helps customers get better ROI will show cost details and stories from other building jobs.

Factor | What to Look For |

|---|---|

Initial Cost | Good price |

Operating Costs | Low energy and fixing costs |

Value Added | Makes lots of blocks, strong and flexible |

ROI | Shows real savings in building projects |

Certifications prove a block making machine supplier follows the rules. Look for suppliers with ISO 9001, CE, and other needed papers. Following building codes means the block making machine will work safely and well. Suppliers with these papers care about making good machines and keeping customers safe.

Note: Always ask for copies of certifications and check if they are real with the right groups.

World-leading AAC block machinery makers use smart machines and care about the earth. Top companies spend money on research and follow tough rules for quality. Picking the right supplier helps your project work well and meet green goals.

Reports from MarketsandMarkets and GlobalData say AAC technology keeps getting better.

Builders want AAC because it saves energy and helps the planet. If you need help, talk to experts or trusted suppliers for advice.

AAC block machinery is equipment that makes autoclaved aerated concrete blocks. These machines mix, cut, and cure the materials. The blocks are light and strong for building. Experts say AAC machinery helps make buildings better for the planet.

Manufacturers use machines and strict checks to keep quality high. Machines watch every step, from mixing to curing. Top companies follow ISO 9001 rules for strong and lasting blocks.

Asia-Pacific, Europe, and Turkey make the most AAC block machines. China and Germany have the biggest factories. Reports show Asia-Pacific makes over 35% of all AAC machine sales.

AAC block machines need ISO 9001, CE Marking, and Pressure Vessel Certification. These papers show the machines are safe and good quality. Experts say to check these papers before you buy.

AAC technology uses natural materials and less energy. The blocks help buildings save power and make less waste. The U.S. Green Building Council says AAC is a smart choice for green buildings.