The World’s Leading Supplier of AAC Production Line

English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The World’s Leading Supplier of AAC Production Line

The World’s Leading Supplier of AAC Production Line

Views: 0 Author: Site Editor Publish Time: 2025-10-11 Origin: Site

Image Source: teeyer-global.com

An AAC block manufacturing plant makes special building materials for new buildings. You use this plant to make AAC blocks. These blocks are light, strong, and save energy. AAC blocks keep heat in and stop fires better than old bricks. They also help builders work faster and easier because they are not heavy. AAC blocks block sound well too. More people want AAC blocks every year. The world market may reach $29.84 billion by 2029. Special machines from top brands like Teeyer help you make good blocks. These machines also help you follow new rules for the environment.

AAC blocks are light and strong. They are easy to move and put in place. This helps workers save time and money.

To make AAC blocks, workers mix sand, lime, and aluminum powder. These blocks keep heat out and do not burn easily.

Builders can use AAC blocks to follow green building rules. The blocks use natural things and help save energy.

New AAC block plants have smart machines. These machines mix, cut, and cure the blocks. This makes work faster and keeps the blocks good.

Picking AAC blocks can help save money for a long time. You pay less for energy and fixing things. AAC blocks are also good for nature.

AAC stands for autoclaved aerated concrete. It is made from sand with lots of silica, lime, cement, and a little aluminum powder. When you mix these things, they react and make lots of tiny air bubbles. These bubbles make the blocks light and simple to move. C-S-H gel and tobermorite are the main chemicals in AAC. They give the blocks strength and help them last. AAC blocks keep heat in and stop fires. In India, many companies use this method to make blocks for all kinds of buildings.

An AAC block manufacturing plant helps builders meet the need for new, green buildings. The plant makes blocks that are lighter than old bricks. This means buildings weigh less and cost less to build. The plant also helps builders follow new rules for green building. Many companies in India use these plants for city projects and big buildings. You can use AAC blocks for houses, schools, hospitals, and offices.

Tip: Using AAC blocks can help you get green building awards and government rewards.

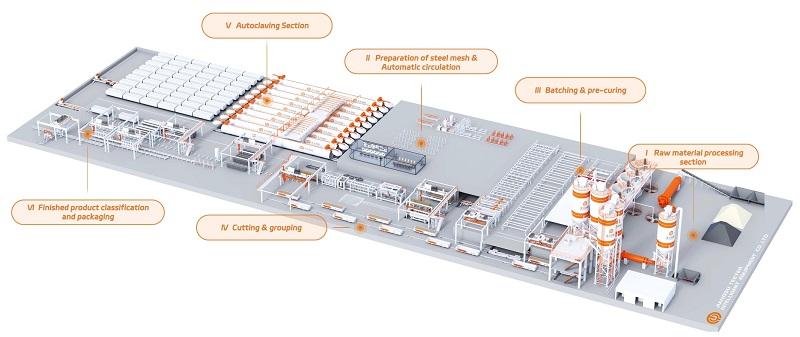

AAC block manufacturing plants use smart machines and a good setup. Top brands like Teeyer make machines that mix, shape, cut, and cure the blocks. The plant has:

Systems to mix and measure the raw materials

Machines to shape the AAC mix

Rooms to let the green cake set

Cutters to make the blocks the right size

Autoclaves to cure the blocks with steam

Cranes and tools to move the blocks

Here is a table that shows how AAC block plants compare to other block plants:

Feature | AAC Block Manufacturing | Other Block Production Facilities |

|---|---|---|

Raw Materials | Silica-rich materials, lime, cement, aluminum powder | Varies, often includes clay or concrete |

Production Process | Mixing, autoclaving, and curing | Usually molding and drying |

Automation | Automated batching and wire cutting | Often less automation |

Lightweight Properties | Yes, much lighter than traditional blocks | Usually heavier |

Insulating Properties | Excellent thermal insulation | Often less effective |

Eco-Friendly Manufacturing | Less energy and raw materials used | More resource-intensive |

Teeyer has over 35 years of experience in this field. They make new machines like air-tilting cutters and robot lines. You get help with green building and setups made for your area.

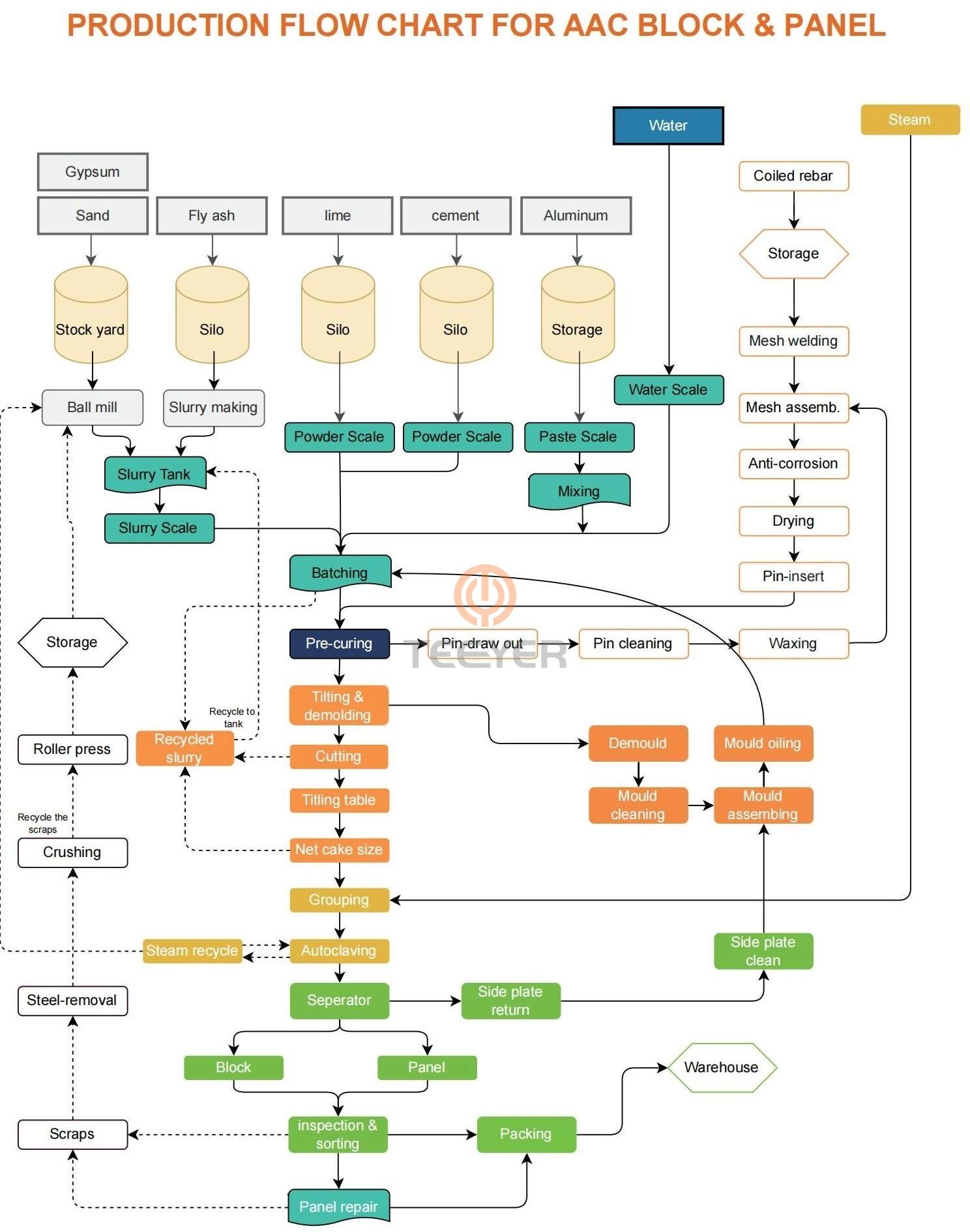

The AAC block manufacturing process has many steps. Workers make blocks in a factory with strict rules. This helps every block be strong and light. AAC blocks are good for new buildings.

You need good raw materials to make AAC blocks. These include:

Cement, which holds everything together

Lime, which helps make bubbles

Silica sand, which adds tiny grains

Aluminum powder, which makes gas when mixed with lime

Water, which mixes all the parts

Gypsum, which helps control how fast it sets

Fly ash, which can be used instead of sand

The quality of these materials is important. If you use the best fly ash, cement, lime, and aluminum powder, your blocks will be lighter and stronger. Good materials help the blocks hold up better. This means the blocks work well in buildings.

First, you get each material ready. Sand or fly ash is cleaned, lime is prepared, cement is stored, and aluminum powder is set out. Machines measure and mix the materials. This makes sure the mix is always the same.

Equipment Type | Description |

|---|---|

Slurry Mixer | Keeps the AAC mix even during pouring. |

Automated Dosing | Weighs and mixes all the raw materials correctly. |

After mixing, you pour the mix into big molds. The aluminum powder reacts with lime and water. This makes hydrogen gas. The gas forms tiny bubbles and the mix grows bigger. The molds let the mix rise and set. You keep the molds in a special room so the mix can set right.

After pouring, you move to molding and pre-curing. You use molds with grease so the mix does not stick. The aluminum reacts with water and lime. This makes hydrogen gas and lots of small bubbles. The mix rises and becomes a “green cake.”

You let the green cake sit and cure for one to four hours. This step is very important. It helps the blocks get strong enough to cut. If you rush, the blocks may be weak. Waiting longer can make the blocks better.

Note: The curing time is needed for strong AAC blocks. If you do not cure enough, the blocks can be weak.

After curing, you take the green cake to the cutting area. Wires cut the cake into blocks of the right size. This makes sure every block is the same and smooth. Good cutting helps builders put blocks together easily.

After cutting, you put the blocks in an autoclave. The blocks get steam under high pressure. This makes the blocks hard and strong. After steaming, you let the blocks cool before moving them.

You check the blocks at every step. This helps you find problems early. Every block must meet the rules.

Quality Control Measure | Purpose |

|---|---|

XRF (X-ray Fluorescence) | Checks what chemicals are in the block. |

XRD (X-ray Diffraction) | Measures how much tobermorite is in the block. |

You look for problems like broken edges or wrong sizes. Machines help you mix and cut the blocks right. You keep machines working well for good results. You check how long blocks cure and test them for strength, water, and fire safety. Before shipping, you look for broken edges and make sure blocks are stacked right.

Tip: Good quality checks help your AAC block plant make strong blocks for every job.

You need special machines to run an AAC block plant. Each machine does a different job in the process. The machines work together to make strong and light blocks. They also help make sure the blocks are the right size. Here is a table that shows the main machines and what they do:

Machine Type | Function |

|---|---|

Raw material silos and weighing systems | Store and measure raw materials for production |

Mixing and dosing units | Combine raw materials in precise proportions |

Casting molds and platforms | Shape the AAC mixture into blocks |

Cutting machines with precision wires | Cut the blocks to specified dimensions |

Autoclaves for steam curing | Cure the blocks under high pressure and temperature |

Control systems and automation | Monitor and control the entire production process |

Each AAC block machine helps keep the work moving. The mixing and dosing units help you get the mix right every time. Cutting machines make sure blocks fit together at the building site. Autoclaves make the blocks strong at the end.

When you set up your AAC block plant, you must think about how big your plant will be. A small plant uses fewer machines and simple setups. A big plant needs more machines and more automation to make enough blocks. The equipment you pick changes how many blocks you can make each day. It also changes how much energy you use.

Production capacity is important. Your AAC block machine should match your project.

Automation helps you use less labor and make more blocks.

Good quality control keeps your blocks safe and strong.

Energy-saving machines help you spend less and protect nature.

Regular care and help from brands like Teeyer keep your AAC block machine working well.

You need to think about the cost of machines and what you will get back.

Teeyer is a leader in AAC block machine technology. They use smart automation, like rotary clamps and robot lines, to make packing and moving blocks faster. Their new ideas for pre-curing and cutting help you make more blocks each day. Some plants now make over 20,000 cubic meters every day because of these upgrades. Teeyer’s smart systems also help you run your plant better and use less energy.

Tip: Picking the right AAC block machine setup helps you make better blocks, save money, and grow your business.

If you use an AAC block manufacturing plant, you get many good things. AAC blocks help keep your house warm in winter. They also keep it cool in summer. The walls are strong and block noise. This makes your home quiet. The blocks are light, so you can move them easily. This saves time and money when building a house. You do not need as many workers because the blocks are simple to handle. AAC blocks are made from natural things. This helps the environment. You can recycle these blocks and make less trash.

Thermal insulation keeps your house comfy.

Sound insulation makes your house quiet.

Lightweight blocks put less weight on your house base.

Fast placement saves time and worker costs.

Natural materials help with green building.

Tip: Using AAC blocks helps you build better houses and meet green building rules.

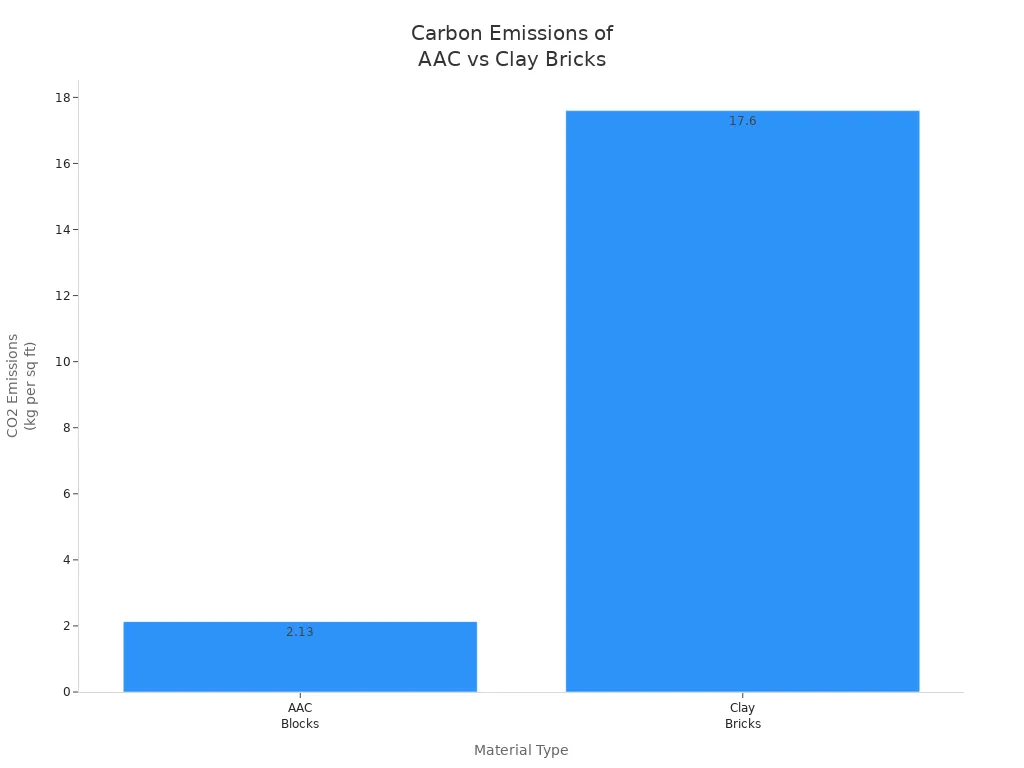

AAC block manufacturing plants are good for the environment. You use less energy to make AAC blocks than old bricks. This means less pollution goes into the air. AAC blocks use fly ash, which is waste from power plants. This cuts down on trash from factories. The blocks are light, so trucks use less fuel to move them. When you build with AAC, you help save trees and use green building materials.

Aspect | AAC Blocks | Traditional Materials |

|---|---|---|

Energy Consumption | Lower | Higher |

Carbon Emissions (per sq ft) | 2.13 kg of CO2 | 17.6 kg of CO2 (clay bricks) |

Transportation Emissions | Reduced | Increased |

Use of Recycled Materials | Yes (fly ash) | No |

Deforestation Impact | Reduced | Higher |

Insulation Properties | Excellent | Varies |

AAC blocks last a long time and do not get damaged by water, fire, or bugs. You spend less money fixing or replacing them. These blocks help your house meet green building rules like LEED and BREEAM.

AAC blocks are better than red bricks and concrete blocks in many ways. AAC blocks cost more for each block. But you save money on workers and energy. You can build faster and need fewer workers. The blocks keep heat in, so you pay less for heating and cooling. AAC blocks are strong and work well for building houses.

Material Type | Unit Cost | Overall Wall System Cost | Thermal Efficiency | Construction Speed | Labor Cost | Energy Savings |

|---|---|---|---|---|---|---|

Red Bricks | Moderate | Higher due to labor | Low | Slower | Higher | Lower |

AAC Blocks | Highest per block | Competitive overall | High | Fast | Lower | Higher |

Concrete Blocks | Competitive/Lowest | Competitive overall | Moderate | Moderate | Moderate | Moderate |

AAC blocks, red bricks, and concrete blocks all last if you use good materials. AAC blocks do not rot or get eaten by bugs. This keeps your house strong for a long time. If you pick AAC blocks, you get many good things and help the planet.

You now understand how an aac block manufacturing plant works and why it matters. When you use aac, you get lightweight blocks that are easy to move and install. These blocks offer strong fire resistance and help keep buildings comfortable year-round. The process is simple:

Mix sand, lime, cement, water, and aluminum powder.

Let the mix create tiny air pockets.

Cut and cure the blocks with steam.

Modern equipment, like automated packaging lines, makes your plant more efficient. As more companies launch new aac plants, you see faster, greener building projects. Choosing aac blocks helps you build safer, smarter, and more sustainable spaces.

You need cement, lime, silica sand or fly ash, aluminum powder, water, and gypsum. These things help make blocks that are strong and light. The blocks also keep heat in and cold out.

It takes about 24 hours to make AAC blocks. You mix the materials, then mold and pre-cure them. Next, you cut, autoclave, and cool the blocks. Machines help make the work faster.

Yes, you can recycle AAC blocks. You crush old blocks into small pieces. These pieces can be used for new building or roads. Recycling helps cut down on waste and supports green building.

AAC blocks keep heat in and block fire and sound. You save money on workers and energy. Using recycled materials and less energy helps the planet.

Tip: Picking AAC blocks lets you build safer, greener, and smarter buildings.